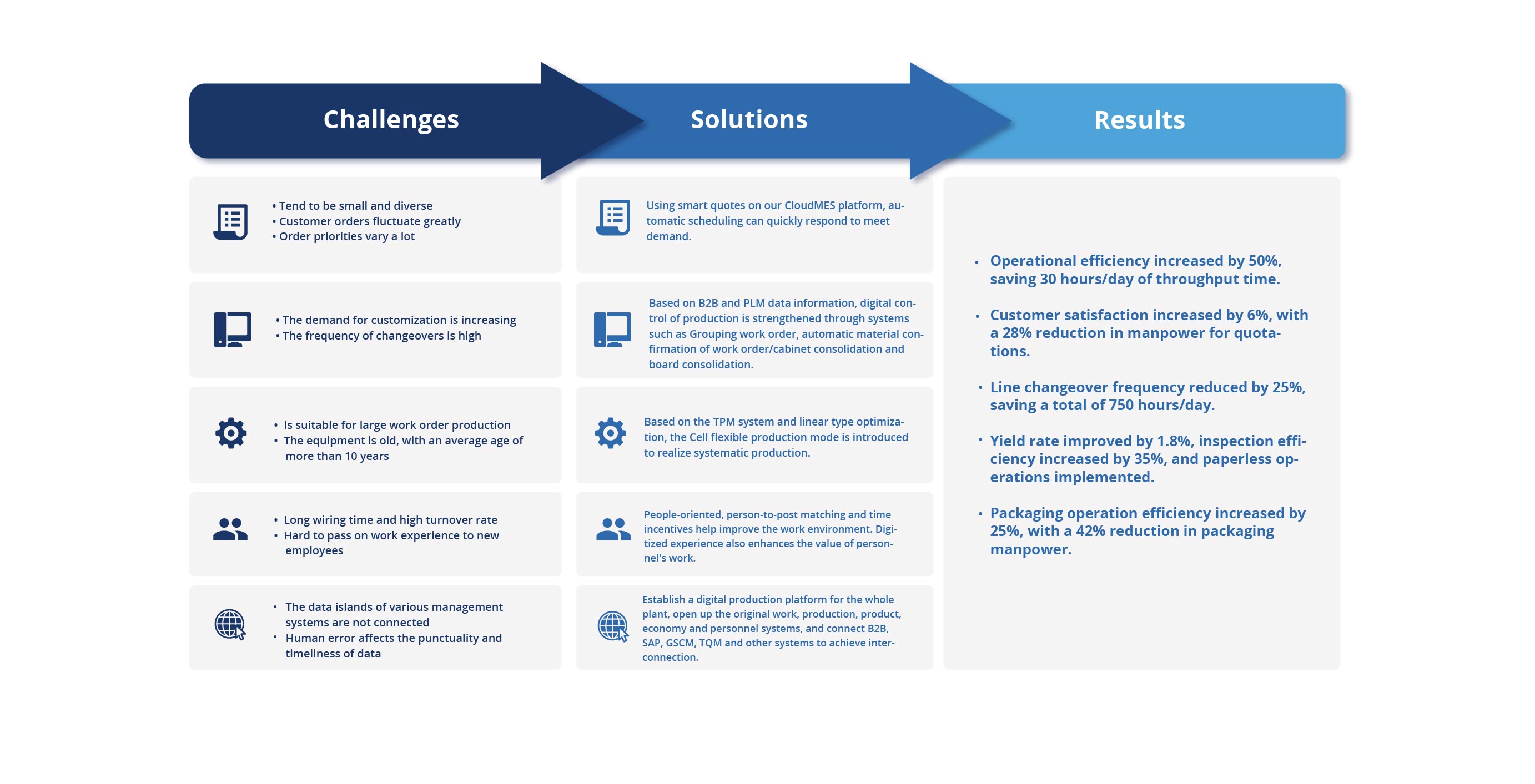

Products tend to be small and diverse and have a short life cycle, resulting in a high frequency of production line changeovers, long wiring time of old equipment, and islands of various management systems, resulting in challenges from orders, products, equipment, personnel and systems, etc. It is urgent to maintain competitive advantage through transformation and transformation.

? Using smart quotes on our CloudMES platform, automatic scheduling can quickly respond to meet demand.

? Based on B2B and PLM data information, digital control of production is strengthened through systems such as Grouping work order, automatic material confirmation of work order/cabinet consolidation and board consolidation.

? Based on the TPM system and linear type optimization, the Cell flexible production mode is introduced to realize systematic production

? People-oriented, person-to-post matching and time incentives help improve the work environment. Digitized experience also enhances the value of personnel's work

? Establish a digital production platform for the whole plant, open up the original work, production, product, economy and personnel systems, and connect B2B, SAP, GSCM, TQM and other systems to achieve interconnection.

? Operational efficiency increased by 50%, saving 30 hours/day of throughput time.

? Customer satisfaction increased by 6%, with a 28% reduction in manpower for quotations.

? Line changeover frequency reduced by 25%, saving a total of 750 hours/day.

? Yield rate improved by 1.8%, inspection efficiency increased by 35%, and paperless operations implemented.

? Packaging operation efficiency increased by 25%, with a 42% reduction in packaging manpower.